HOW PREVENTING GLITCHES IN RECLAIMING POSSESSIONS WORTH

12 000 000 EURO?

The fire broke out in one of the loading candy factories covering the 5500 square meters facility in soot. This includes the venting system as well as 12 million worth of equipment.

The major question for the factory's management was what they were supposed to do with the warranty on the machinery as they were only 1.5 years old.

There were three optionions considered by the directorate:

- To write down the damaged equipment, get paid from the insurance company and buy new one.

- To disassemble the machinery, transport it and renovate it elsewhere.

- To renovate equipment on-the-spot.

START OF WORK

The tender was launched in which we participated with other company. First company inspected the premises of the facility and then made an offer.

The tender was launched in which we participated with other company. First company inspected the premises of the facility and then made an offer.

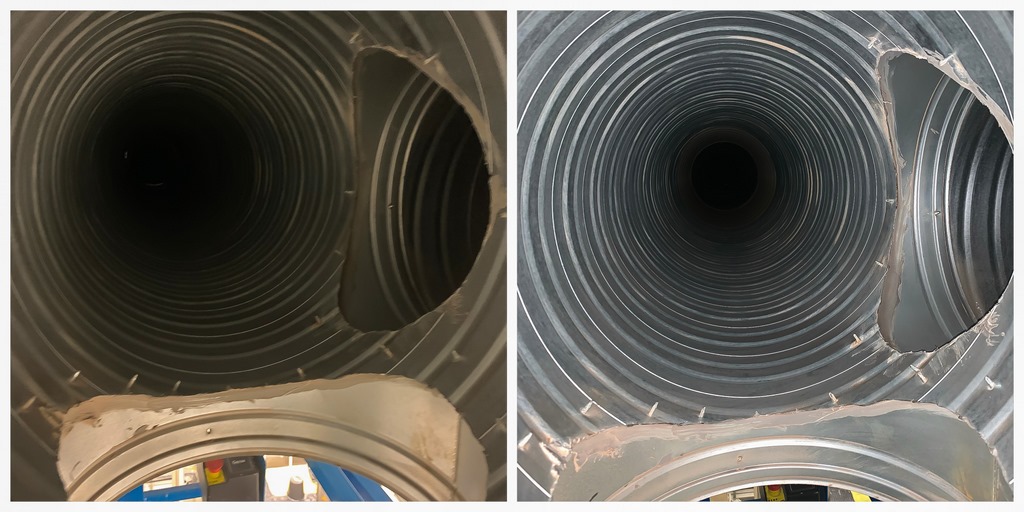

Our team of specialists also went there in order to examine the situation. The chemical samples have been collected and it was found that the level of the chloride exceeds the permitted norm. Our experts explained to the customer whole operation and technologies we offer to use. We have proposed the restoration of equipment without dismantling. Specialists outlined methods we would use to clean the place and what is more important retrieve machinery as well as venting system. Conventional process of remedial actions was not possible due to the fact that we were dealing with food industry.

The Price offered by the first company was definitely lower, but their specialists could not even explain to the customer the process of their work.

The Price offered by the first company was definitely lower, but their specialists could not even explain to the customer the process of their work.

We were pleased that the client chose our services. We were asked to start working as soon as we can. Our due date was 2 months, since the longer the soot remains on the equipment the greater likelihood of serious damage to machinery. We managed to agree on a plan of work, estimate the amount of the insurance, and get down to work.

WORKFLOW

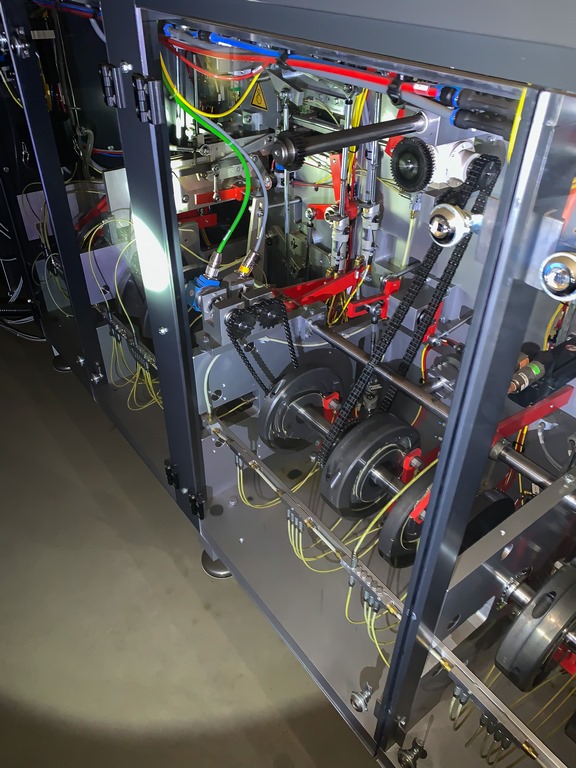

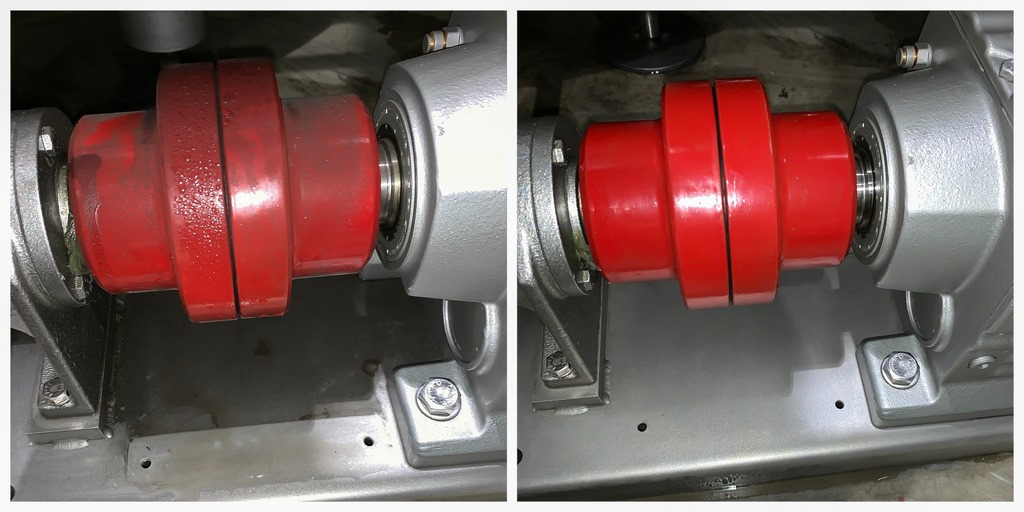

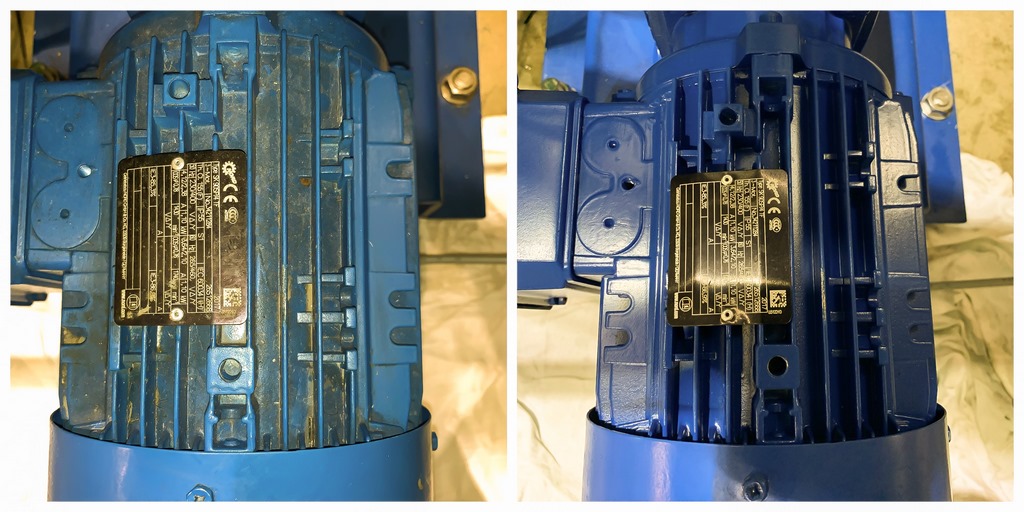

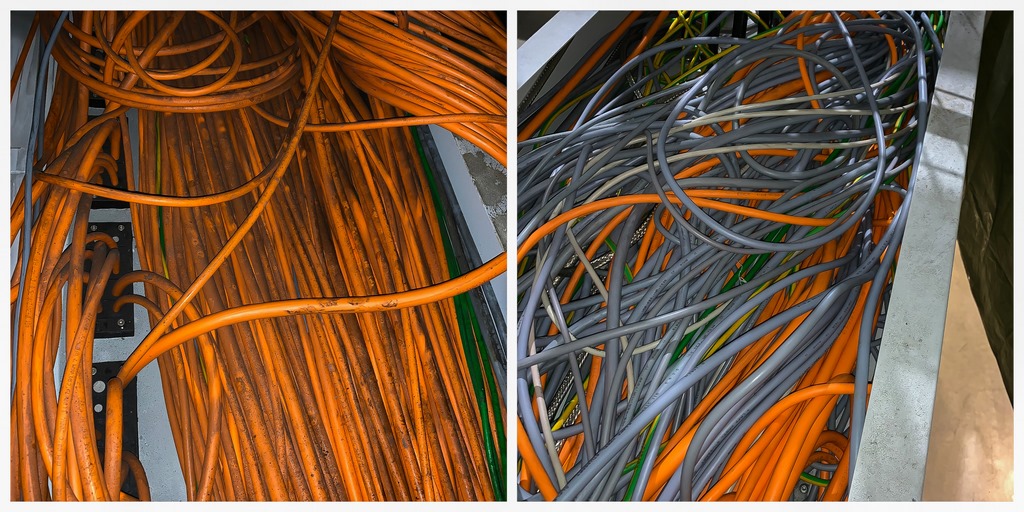

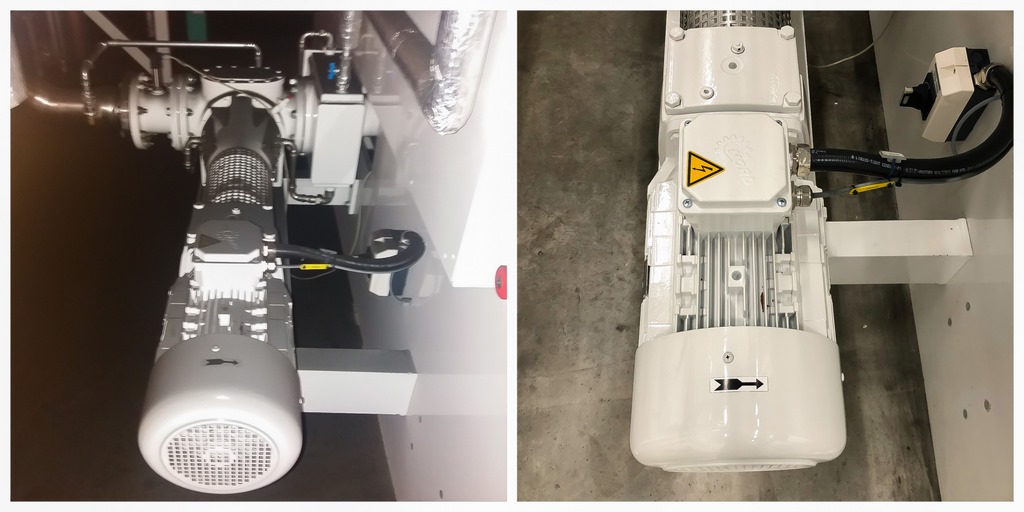

Cleaning all electronic equipments turned out to be the toughest part of our work, since it required high-precision to do everything precisely and properly. We had our Spanish colleagues helping us with cleaning electronics since they are more experienced than we were. We also delivered additional equipment from Spain. Electrical panels, various motors, uninterruptible power supplies, shields with high voltage, equipment with built-in automation those are few examples of things we had to clean, some of them even under voltage. During cleansing procedure we detected defective parts that could cause equipment failure in the future. Thanks to that our Customer was able to fix them before they actually get serious.

Cleaning all electronic equipments turned out to be the toughest part of our work, since it required high-precision to do everything precisely and properly. We had our Spanish colleagues helping us with cleaning electronics since they are more experienced than we were. We also delivered additional equipment from Spain. Electrical panels, various motors, uninterruptible power supplies, shields with high voltage, equipment with built-in automation those are few examples of things we had to clean, some of them even under voltage. During cleansing procedure we detected defective parts that could cause equipment failure in the future. Thanks to that our Customer was able to fix them before they actually get serious.

After that our work was audited by Austrian engineers so they could safely connect machinery. The engineers admitted that they were pleasantly surprised, because for the first time in many years of practise, they could see such professional and clean work. Positive feedback always make us happy and convinced that our hard work is appreciated and worth trying our best.

After that our work was audited by Austrian engineers so they could safely connect machinery. The engineers admitted that they were pleasantly surprised, because for the first time in many years of practise, they could see such professional and clean work. Positive feedback always make us happy and convinced that our hard work is appreciated and worth trying our best.

THE END OF WORKS

During our work, we had brief meetings with the client in order to discuss cleansing progress. At one of them we were asked to increase the speed of work to complete the task even faster. We succeeded to modify our plan without any increase of the budget, and accomplished our task 2 weeks earlier.

During our work, we had brief meetings with the client in order to discuss cleansing progress. At one of them we were asked to increase the speed of work to complete the task even faster. We succeeded to modify our plan without any increase of the budget, and accomplished our task 2 weeks earlier.

Then we did the tests again. It turned out that each of the collected samples was within the norm. As soon as we made sure that was safe and our work was =done, the factory has resumed production and is functioning at full capacity till now.

ABOUT US

LV GROUP is a company founded in 2008, which is currently a leader in Europe in the field of restoration and renovation. We specialize in eliminating the consequences of fire and flooding, returning the property to its original appearance and functionality.

- from damage by fire and soot

- after flooding

- from the effects of mold

- other damage

- state-of-the-art equipment and chemical developments for quick and cost-effective recovery

WE ARE ON THE MAP:

CONTACTS:

| +371 67 262 636 | |

| +370 646 88490 | |

| Follow us Linkedin | |

| http://bmsbaltic.eu | |

| Dzirkaļu iela 44, Rīga |